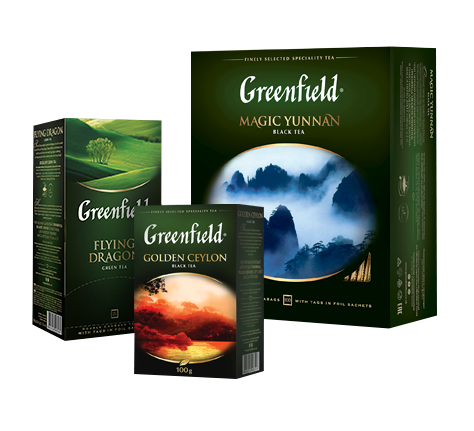

GOURMET TEA COLLECTION

The Gourmet Tea Collection is characterized by the harmonious blend of classical flavors, a tribute to tea traditions and the exquisite beauty of whole tea leaves. The collection represents noble varieties of large-leaf tea — tightly twisted leaves that preserve all the natural energy and strength, revealing the depth, richness, and authentic taste and aroma of traditional tea.